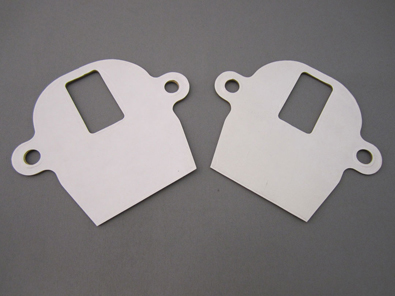

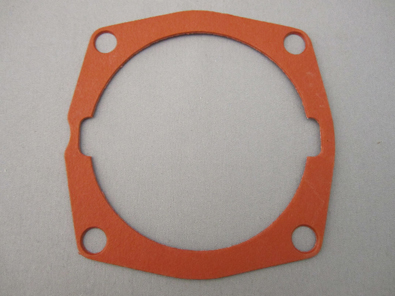

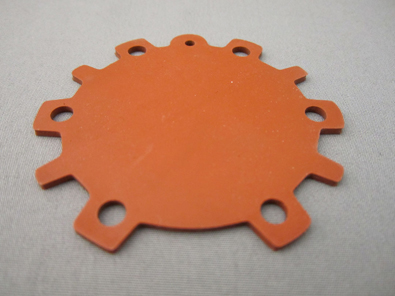

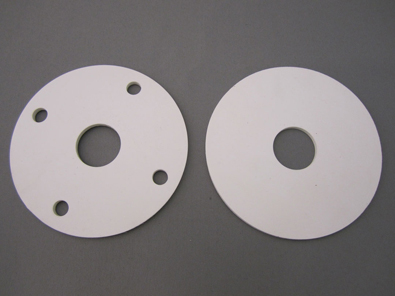

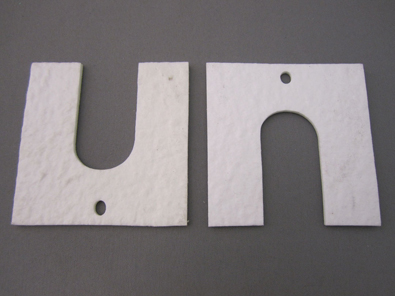

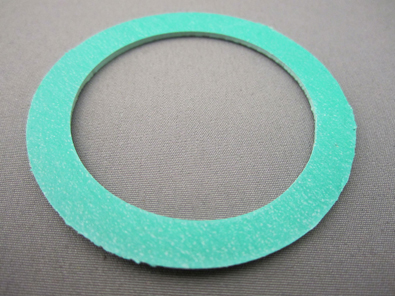

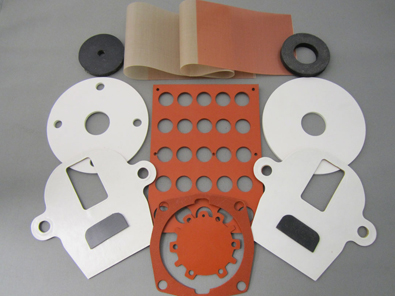

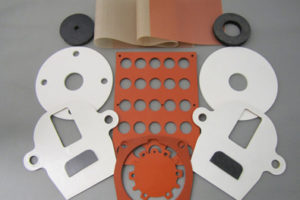

At Quick Cut Gasket & Rubber Corporation, we offer both standard and custom gaskets in a range of production volumes. Gasket types include, but are not limited to, diaphragm, magnetic, pipe, flange, and compressor gaskets. Die cutting is used to produce medium to high volume work, while small volumes can be hand cut by experienced craftsmen using a tracing template. Our team has a very long tenure with the company and we take pride in knowing that customers count on our products to keep their pumps, compressors, and other equipment functioning properly.

Single piece gaskets up to 4′ wide and 3″ thick can be cut. Larger sizes can be fabricated by creating a sectioned gasket assembly. Dimensional tolerances can be held to ±0.020″ for die cut gaskets and ±0.062″ for hand cut work. A comprehensive selection of gasket materials is available depending on the application requirements. Available materials include EPDM, neoprene, silicone, multiple types of rubber, felt, and PTFE. Specialty materials including adhesive backed, cloth inserted, or FDA approved materials can also be used. Gaskets can be cut from sheets or large rolls. The hardness range of our material falls along the Shore “A” durometer scale.

Lead times are very fast, average less than 48 hours for small orders and 1 to 2 weeks for larger orders. This flexibility allows us to serve customers’ immediate needs. If a large order is needed immediately, a small run quantity can be quickly produced and shipped to prevent any downtime. Material certification and inspection documentation can be provided as specified. For more information about our standard and custom gaskets, see the table below, or contact us directly.

Standard & Custom Gaskets Capabilities

- Primary Capabilities

-

Die Cutting

Tracing Template

- Gasket Types

-

Compressor

Diaphragm

Flange

Laminated

Magnetic

Metal

Packing

Pipe

Ring

Tank

UL Gaskets

Valve

Weatherstripping

- Form

-

Roll

Sheet

- Material

-

Compressed Non-Asbestos Fiber Composite

Buna-N – Rubber & Sponge

EPDM – Rubber & Sponge

Neoprene – Rubber & Sponge

Silicone – Rubber & Sponge

Viton® Rubber & Sponge

Red Rubber

Pure Gum Natural Rubber

Cloth Inserted Rubber-Diaphragm

FDA Materials

Garlock Sheet

Vellumoid (Vegetable Fiber)

Cork

Cork & Rubber

SAE Felts

Flexible Graphite

Latex

UHMW

HDPE

LDPE

Polycarbonate

Polypropylene

PETG

Polyurethane

Sponge Rubber – Open & Closed Cell

PTFE

Acco-Pac Style Materials

SBR

Butyl

Flexatalic

Adhesive Backed

- Durometer

-

“A” Scale

- Color

-

Black

White

Red

Blue

Custom

- Resistances

-

Acid

Oil

Ozone

Heat

- Temperature Range

-

-300 °F to 750 °F

- Pressure Range

-

Up to 200 psi

- Thickness

-

.006″ to 3″

- Inner Diameter

-

Down to 1/16″

- Outer Diameter

-

Up to 5′

- Tolerance

-

± .020″ (Die Cut)

± .062″ (Hand Cut)

- Inspection

-

Visual

In-Process

Final

- Testing

-

Hardness

Durometer

Thickness

Tolerance

- Documentation

-

Material Certification

Inspection Report

- Additional Services

-

Laser Tooling

Assembly

Special Packaging

- Production Volume

-

1 to 1,000,000 pieces

- Typical Lead Time

-

1 to 2 weeks

24 to 48 hours (Small Quantities)

Just-In-Time Deliveries

Additional Information

- Industry Focus

-

Food and Beverage

Automotive

Airline

Military

Compressor

Municipalities

Electrical

Printing

Replacement Parts

Hydraulic

- Intended Applications

-

Grommets

Washers

Bumpers

Spacers

Anti-Vibration Pads

Conveyor Pads

Stoppers

Rubber Plugs

- Industry Standards

-

ASTM

FDA

Mil-Spec

UL

- File Formats

-

PDF

JPG