At Quick Cut Gasket & Rubber Corporation we utilize over 41 pieces of precision production machinery to help fulfill a variety of sealing and rubber cutting needs.

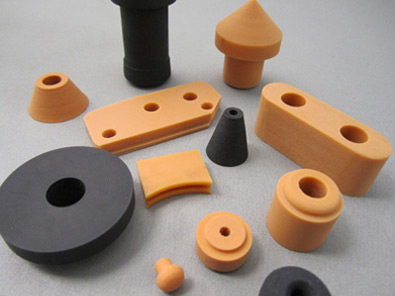

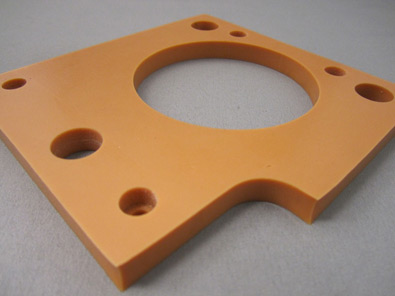

One of our areas of expertise is our ability to manufacture custom rubber products that are made from scratch, eliminating high minimums and costly tooling charges. Our two to four step machining processes includes boring, drilling, fine finishing, and grinding of surfaces and cylindrical items. Our advanced milling machines, grinders, and drill punchers allow us to create products from .187″ to 5″ in diameter and with a thickness from .062″ to 3″, all to tolerances of ±.010″.

The ability to manufacture and distribute cut rubber products from a variety of materials including silicone, polyurethane, PTFE, and many others makes our services ideal for components used in a number of industries including automotive and military. All work goes through in-process inspections including visual and final inspections as well as our own high standards of manufacturing quality, which are in full compliance with ASTM, FDA, UL, and Mil-Spec standards.

Since 1964 Quick Cut has been a leader in the industry with little to no employee turnaround, and many have tenure of 24 years or longer. This allows us to perform close, hands on supervision of work while offering low rejection ratios and the ability to fulfill most orders within 24-48 hours.

To learn more about our custom rubber machining, contact us or see the table below.

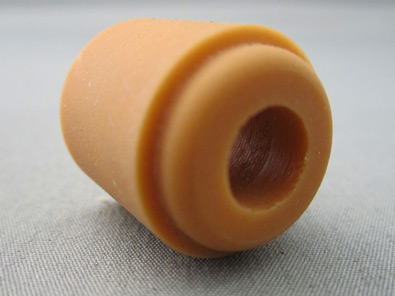

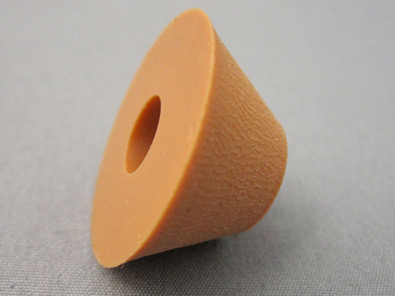

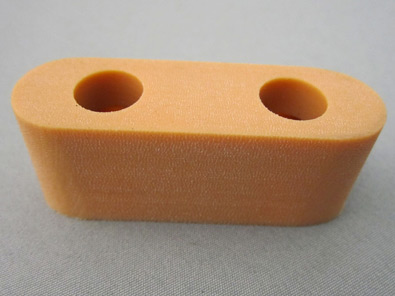

Examples of Our Work

Custom Rubber Machining Capabilities

- Machining Processes

-

Boring

Grinding (Surface and Cylindrical)

Drilling

2 to 4 Step Processes

Fine Finishing

- Equipment

-

Milling Machines

Surface Grinders

Inverted Grinders

Drill Punches

- Materials

-

Neoprene

Buna-N

EPDM

Viton

Silicone

Polyurethane

FDA Materials

PTFE

Cloth Inserted

Cork

Rubber

- Part Diameter

-

187″ – 5″

- Part Thickness

-

.062″ – 3″

- Tolerance

-

± .010″

- Inspection

-

Visual

In-Process

Final

- Testing

-

Hardness

Durometer

Thickness

Tolerance

- Documentation

-

Material Certification

Inspection Report

- Additional Services

-

Laser Tooling

Assembly

Special Packaging

- Production Volume

-

1 to 1,000,000 pieces

- Typical Lead Time

-

1 to 2 weeks

24 to 48 hours (Small Quantities)

Just-In-Time Deliveries

Additional Information

- Industry Focus

-

Food and Beverage

Automotive

Airline

Military

Compressor

Municipalities

Electrical

Printing

Replacement Parts

Hydraulic

- Intended Applications

-

Grommets

Washers

Bumpers

Spacers

Anti-Vibration Pads

Conveyor Pads

Stoppers

Rubber Plugs

- Industry Standards

-

ASTM

FDA

Mil-Spec

UL

- File Formats

-

PDF

JPG