At Quick Cut Gasket & Rubber Corporation we provide easy and fast access to manufacturing of custom parts. An expert in rubber extrusion and machining, we are able to take specific customer designs and manufacture them to advanced levels of quality using the most advanced rubber and polyurethane materials.

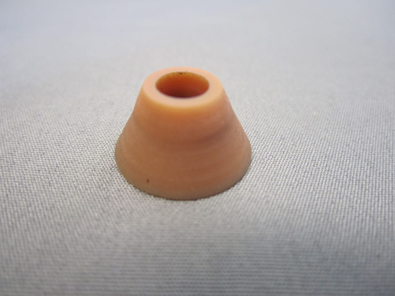

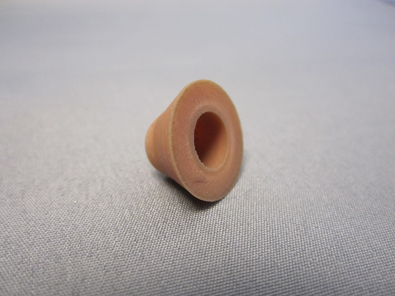

We were recently contracted by an automotive industry customer interested in fabricating a small part out of extruded rubber. Measuring 0.6″ by 0.325″, this small part was to be made from Armstrong 670 polyurethane according to tight tolerances and specific durometer ratings. The customer chose us specifically due to our past experience with the required material for this application.

We created a fabrication process that combined standard extrusion of the polyurethane material along with milling, drilling, and finishing steps. A combination mill and drill press as well as an inverted grinder were utilized for the manufacturing phase, allowing us to achieve tolerances of +/-.010. First article, in process, and after process evaluation were used to ensure quality of the material as well as the necessary RMS surface ratings.

We manufactured 350 units on a less-than one week lead time, a performance advantage made possible by our in-house manufacturing capabilities. The customer was 100% satisfied with the product results, with no pieces rejected.

We manufactured 350 units on a less-than one week lead time, a performance advantage made possible by our in-house manufacturing capabilities. The customer was 100% satisfied with the product results, with no pieces rejected.

For more information about our capabilities or other work experience, see the table below or feel free to contact us directly.

Rubber Part Project Highlights

- Project Name

-

Rubber Part

- Project Description

-

This is used in an automotive application.

- Capabilities Applied/Processes

-

Primary:

Rubber Extrusion

- Equipment Used to Manufacture Part

-

Milling/Drilling Press

Inverted Grinder

- Overall Part Dimensions

-

Length: 0.6″

Width: 0.325″

- Tightest Tolerances

-

+/-.010

- Material Used

-

Armstrong 670 – Polyurethane

- Material Finish

-

R.M.S. Finish

- In Process Testing/Inspection Performed

-

First Article/During Run/After Run

- Industry for Use

-

Automotive

- Volume

-

350 pieces

- Delivery/Turnaround Time

-

Within 1 week

- Delivery Location

-

US